S&S

In 1958 George Smith and his wife Marjorie started a small company called S&S Cycle. Located in Blue Island Illinois, the Smith´s new company began by selling lightweight aluminum pushrods for Harley-Davidson Motorcycles. George Smith´s vision was clear and simple: "I want to make all bikes go faster". This was a goal he pursued for the rest of his life.Even through George an Marge Smith have passed away, the company they founded still shares that vision and S&S Cycle has grown to be the worlds most respected manufacturer of high performance engines and components for American V-Twins.

Visit WebsiteProducts by S&S in our web shop:

S&S HI-4N Ignition

Throttle Housings for S&S Grip Assemblies

Left Grips for S&S Grip Assemblies

Fuel Line Insulator

S&S Twin Cam Style Oil Filter Bracket

S&S Tapered Quick Set up Kits with Air Cleaner and Exhaust

S&S KN-Series Engines

S&S SH80-Series Shovelhead Style Engines

S&S SH93-Series Shovelhead Style Engines

S&S V80-Series Evo Style Engines

Oil Filter Cartridges for S&S SH and V-Series Engines

S&S Stock Bore Stroker Pistons — Knucklehead, Panhead, Shovelhead

S&S Super Stock Generator Cases →1969

S&S Super Stock Alternator Crankcases 1970→

S&S 883 → 1200 cc Conversion Kit

S&S Forged Pistons 3-5/8” Big Bore Evo Stock Heads 4-1/4” and 4-1/2” Stroke

S&S O-Ring Manifold Clamps

S&S Cylinders for Knucklehead

S&S Rubberband Manifold Clamps

S&S Forged Pistons 3-5/8” Big Bore 1936-1984 OHV

S&S Adjustable Support Bracket

Replacement Pistons for S&S 4” Big Bore Kit

S&S Cylinders for Shovelhead with Pistons

Replacement Valves for S&S Super Stock Evolution Cylinder Heads

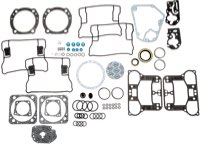

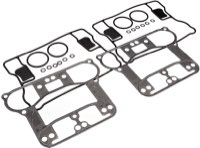

S&S Gasket Kits for Engines: P and SH Series

S&S Gasket Kits for Engines: S&S V Series

S&S Cylinders for Evolution Big Twin

S&S Teardrop Air Cleaners for OEM Carburetors

S&S Mini Teardrop Air Cleaners

S&S Nostalgic Air Cleaner Cover

S&S Rubberbands for Manifolds

S&S Power Tune Duals Header Pipes

Replacement Heat Shields for S&S Power Tune Duals Header Pipes for Touring 1995→

S&S Nut Kits for Cylinder Base: Big Twin 1936-1984

S&S Super B/E Manifolds for Stock Engines

Manifolds for Shovel Sidewinder Engines

Parts for S&S Super E and Super G Manifolds

S&S Gaskets for S&S Manifold Flanges to S&S Cylinder Heads

Replacement Parts for S&S Air Cleaners

S&S Breather Valves

S&S Crankcase Breather Reed Valve Evolution

S&S Cam 561 for Evolution Big Twin

S&S Cams for Twin Cam with Chain Drive

S&S/Gates High Strength Final Drive Belts

S&S 510 G Cams for Twin Cam with Gear Drive

Gaskets for S&S Carburetors to Air Cleaner

O-Rings for S&S Super E/G Crankcase Breather Bolts

S&S New Style Stock Replacement 1200 cc High Compression Pistons

S&S Tappet Guides for Evolution Big Twin

S&S Cover for Air Horns

S&S Tappet Guides for Twin Cam

S&S Pistons Evo Sportster Conversion 883cc-1200cc

S&S Tappets for Knucklehead

S&S Tappet for Evolution Big Twin and Sportster

S&S Semi Solid Adaptor for Evolution Big Twin

S&S Breather Conversion Kits

Gaskets for S&S Float Bowls

O-Rings for S&S Accelerator Jets

O-Rings for S&S Accelerator Pump Cover

Oil Seal for S&S Kicker Covers

O-Rings for S&S Carburetors to Manifold and Insulator Block

O-Rings for S&S Float Valve

O-Rings for S&S Idle Adjuster Screw

S&S Pushrods for Panhead and Shovelhead

S&S Solid Lifter Kit for Shovelhead

S&S Pushrods for Evolution Big Twin

S&S Timesaver Pushrods for Evolution Big Twin

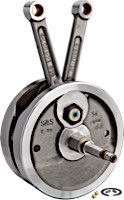

S&S Flywheel Assemblies

Counter Nuts for S&S Solid Lifter Kit

Filter Element for S&S High-Flow Filter Kit

S&S Gaskets for Cylinder Head: Knucklehead 3-5/8 ” Bore

S&S Gaskets for Oil Return Lines on S&S Knucklehead Cylinder Heads

S&S Gaskets for Cylinder Base: Knucklehead 3-5/8 ” Bore

S&S Filter Element for S&S Stealth Air Cleaner

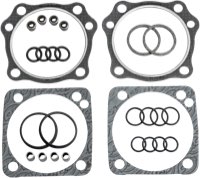

S&S Gasket Kits for Rocker/Valve Spring Covers: KN Series Engines

Filter Element for S&S Induction System

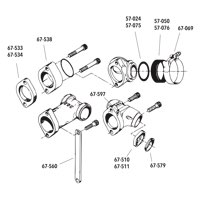

S&S Rebuild Kits for Oil Pumps: Pre-Twin Cam

S&S Gasket Kits for Oil Pumps: Pre-Twin Cam

S&S Piston Ring Sets 3-5/8” Big Bore for Forged Pistons OHV 1936-1984

S&S Piston Ring Sets 3-5/8” Big Bore for Forged Piston Panhead/Shovelhead

S&S Reducer Bushings

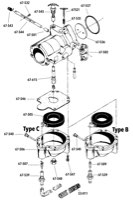

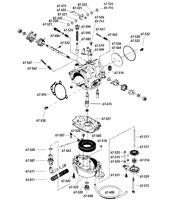

S&S Super B Carburetors

S&S Super E Carburetor Kits

S&S Gaskets for Cylinder Head: Panhead 3-5/8 ” Bore

S&S Super E Carburetor Only

S&S Super E Carburetors Only - Black Series

Main Jets for S&S Carburetors

S&S Gaskets for Cylinder Base: Panhead and Shovelhead

S&S Rocker Arms and Shafts

S&S Rocker Shafts

S&S Gaskets for Cylinder Base: Shovelhead 3-5/8” Bore

Intermediate Jets for S&S Super B, D, E and G

Rebuild Kit for S&S L-Series Carburetors

Rebuild Kit for S&S Super B Carburetors

Master Rebuild Kits for S&S Super E and G

Standard Rebuild Kits for S&S Super E and G

Basic Rebuild Kit for S&S Super E and G

Rebuild Kit for S&S Super E and G Accelerator Pumps

S&S Gasket Kits for Rocker Covers: SH Series Engines

Swivel Fitting Fuel Line Kit S&S Super E and G

Replacement Parts for S&S Super B

S&S Gaskets for Cylinder Head: Shovelhead 3-1/2 ” and 3-7/16 ” Bore

S&S Gaskets for Cylinder Head: Shovelhead 3-5/8 ” Bore

O-Rings for S&S Shovelhead Rocker Covers

Replacement Parts for S&S Super E and Super G Carburetors

Replacement Float Bowls for S&S Super B

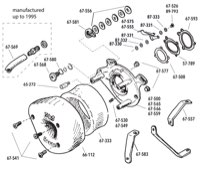

S&S Super Stock Shovelhead Cylinder Heads

Shovelhead Top End Kits

S&S High-Flow Filter Kit Super E and G

S&S Rockerboxes

S&S Gasket Kits for Cylinder Head and Base: V and T Series Engines

S&S Late to Early Pinion Shaft Conversion Kit

S&S Connecting Rod Kits

S&S Gasket Kits for Rocker Covers: Evolution Engines

S&S Gaskets for Cylinder Head: Evolution 3-5/8 ” Bore

S&S Roller Rocker Arms

S&S Gaskets for Cylinder Base: Evolution 4 ” Bore

S&S Gaskets for Cylinder Base: Evolution 3-5/8 ” Bore

S&S Gaskets for Cylinder Head: Evolution 4 ” Bore

Seal Washers for S&S Rocker Cover Screws

S&S Rocker Arms Evolution and Twin Cam

S&S Rocker Arm Shafts Evolution and Twin Cam

S&S Gasket Kits for Rocker Covers: Twin Cam Engines

S&S Gasket Kits for Oil Pumps: Twin Cam

S&S Sidewinder T-Shirts

S&S Serious Power T-Shirts

S&S Stroker Power T-Shirts

S&S Strips T-Shirts

S&S Stock Bore Stroker Pistons for Twin Cams

S&S Genuine Motor Parts T-Shirts

S&S Main Jet Tool

S&S Going Fast T-Shirts

Main Jets for S&S Carburetors

S&S Flywheel Fixing Brackets

S&S Circuit Breaker and Generator Drive Gears

S&S Compression Release Socket Kit

Individual Thrust Washers for Breather Valves

S&S Tappet Block Alignment Tool

Generator Style Gear Covers 8 Rib 1936-1953

Generator Style Gear Covers 4 Rib 1954-1962

Drilling Jig for S&S Oil Pumps

S&S Gear Covers

S&S Sockets for Main Shaft and Counter Shaft Bearings

S&S Oil Pumps

S&S High Volume High Pressure Oil Pump Evolution

S&S Oil Pump Gears for OHV Big Twins Aluminum Pumps

Breather Valve for S&S Oil Pump

19-585

12-148

63-200

63-206

63-202

63-204

57-024

74-435

67-005

67-008

67-058

80-283

80-284

80-285

80-297

80-298

80-299

80-300

80-301

80-302

80-303

80-304

80-305

80-306

80-307

80-308

80-309

64-330

67-518

67-606

67-524

61-501

61-503

55-074

67-520

55-075

64-336

55-072

86-116

67-542

67-333

61-451

61-470

60-465

60-471

60-477

59-860

59-862

59-863

60-601

61-473

61-474

62-628

62-630

67-545

60-755

60-753

60-108

55-423

60-149

60-479

60-774

62-019

62-029

62-112

62-028

60-834