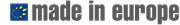

The Cyclery Classic Springer Forks

- Springer fork »Type 1937-1938« by The Cyclery

- fits Knucklehead 1936, Big Twin 1937-early 1946

- steel, bare, internal thread neck post: 3/4”-14 UNS, external thread neck post: 1”-24 UNS

- length: 48.5 cm

- rake: 0 °

- length over/under stock: stock

- with grease nipples 1924-early 1938 and grease nipples late 1938→

- replaces Harley-Davidson part number HD 2601-36, and 45515-36

- Europe

- gross weight: 20 kg

Complete and accurate reproduction of the classic H-D Springer fork (Inline) as used by the factory on Big Twins 1937-1938. Manufactured just like back in the good old times, i.e. with forged legs and connecting components, which makes them equal to the original counterpart concerning stability and service life.

Use this top-quality fork as stock replacement for your restauration or as a part of your chopper or bobber project-bike. The special features are:

- Bare - allows an individual finish of the fork

- Narrow 1936-1937 type mudguard mount

- Completely brazed

- Brake anchor mount for drum brake are soldered just like stock

- "Swept-forward" rigid fork as used by the factory 1936-1940

- Rockers are round at the top, i.e. they have no raised sprues for the grease nipples

- Grease nipples for the guide bushings on the upper triple clamp point inwards, as common in 1936-1938

- Threaded hole on the rigid fork for the brake control coil clip is slightly off-center as it was fitted from late 1937 onwards

- The dimensions of our standard forks are exactly the same as for the original Springer forks (48,5 cm = 19” from center of wheel axle to lower neck bearing seat).

This fork features a fork stem that works with the included centering collar for 1936-up ball bearings. It is not drilled for the 1948→ steering head lock.

Length is measured from axle center line to seat of lower steering head bearing.

Internal Threads on the Upper End of the Legs

For custom riser installation the fork legs have M20x1.5 internal threads at the upper end and accept riser adapter studs or plugs which are available separately; an extra added by the manufacturer which saves you a lot of work and axle grease.

Inline vs. Offset

Classic Springer Forks are produced for different frame rakes.

- In the beginning, both the main tubes and the steering stem were in the same plane. This is called "inline". The rake is 0°. Of this type were all 45” Springer forks 1936-1957 and all Big Twin forks 1936-1945.

- From 1946 onwards the Big Twins had the neck angle increased to 30°. To maintain fork inclination and ground clearance, the steering stem was tilted to the rear by 3°. We call these forks Offset -3°, they were stock on 1946-1948 Big Twins.

- When building a bike with ≥+8” extra long forks you don’t want the steering neck so high and inclined that the bike is difficult to steer. Therefore such forks are manufactured with a positive rake, i.e. the steering stem is inclined to the front by 3°. We call these forks Offset +3°.

The sketch shows the placement of the lateral tubes and steering stem seen from the drivers place. Now it is clear, too, why there have to be three different types of top trees or handlebars for Classich Springer forks.

These forks are delivered pre-assembled but not ready to install. The rocker axle nuts are not end-tight, nor are the tab washers bent. Please apply varnish or coating BEFORE final asselmbly to insure trouble-free fork performance.

1.) The pivot point of the brake shackle on the backing plate or caliper bracket must not be positioned vertically above or in front of the wheel axle (driving direction). In this case the moving forces in your fork parallelogram will be reversed and the fork will rebound instead of being compressed when you apply the brake. This will generate very high forces to impact on your rigid fork leg with possible damage.

2.) Caliper bracket or drum brake backing plate must float on the wheel axle. If not, the fork will rebound as well when applying the brake. Result: see above.

Accessories:

15-107

Bearing Adjuster Nuts for Classic Springer Forks

Steering Head Nuts for Classic Springer Forks

Speedster Hollywood Handlebars

The Cyclery Apron Guards

Bates Riser Adapters

Ride Controls for Classic Springer Forks

Standard Handlebars

Faber Cycle Flanders #0-HD Handlebars

Faber Cycle Stelling & Hellings Top Fork Clamps

See also:

The Cyclery Springer Front Fenders for Big Twin and Servi-car

Hanson Roll-Up Windshields

Springer Headlights 6-1/2”

OEM Style Springer Brake

Have any questions?

Our service team will be glad to help out: Mondays - Thursdays 08:00-17:00 CET, Fridays 08:00-16:00 CET, Phone: +49 / 931 250 61 16, eMail: service@wwag.com